The Advantages of Rubber Seals

Rubber seals prevent lubricating oil from leaking. The seals close spaces between stationary and moving parts and are vital in precision bearings. Rubber also provides an airtight and watertight fit and is a popular choice in the aerospace and automotive industry.

1. Temperature Resistance

Rubber seals can withstand extreme temperatures and variations. For instance, silicon rubber seals will withstand temperatures as low as -100 degrees Celsius and up to 310 degrees Celsius. The wide range makes rubber seals ideal for applications with massive temperature swings.

Rubber seals will remain functional despite temperature variations and mold to the contours of the groove. The seals offer a high degree of flexibility and adapt to the pressure without breaking apart. Rubber seals also retain flexibility at low temperatures.

2. Comparative Durability

Rubber is more durable than other materials and forms an impervious airtight and watertight seal. More importantly, rubber is flexible and provides resistance in proportion to the pressure applied. Rubber seals also maintain integrity for a longer duration.

Although there are breaking points to how long rubber seals will last under pressure, they are more impressive than other options and require less frequent replacement. Rubber will last longer than polyurethane, polyacrylate, and FEP seals.

3. Highly Malleable

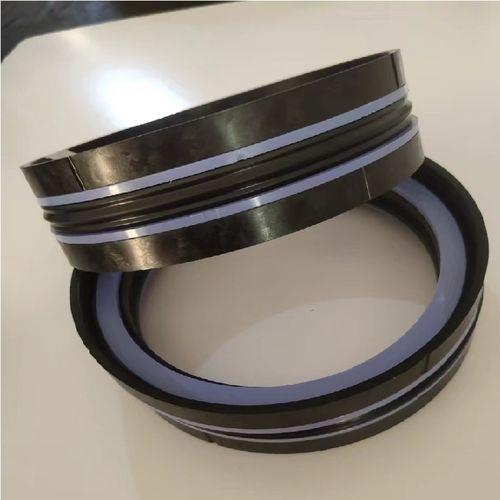

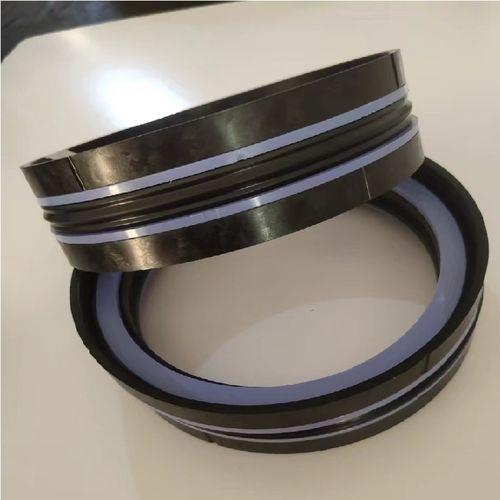

Rubber is easy to mold into different sizes and shapes used in a wide range of applications. O rings, U rings, and V rings are popular examples of rubber seals. Others are rotary oil seals, spring-installed seals, bearing isolators, and clearance seals.

4. More Compatible

Rubber is compatible with many materials and can complement other substances to improve the seal’s integrity. Rubber treatment can improve compression capabilities, tolerance to extreme temperatures, and overall longevity, and also prevent seal failure.